Constraints Tables¶

User may add custom constraints with respect to capacity or counts. These tables are:

Flow Constraint

Flow Count Constraint

Inventory Constraint

Inventory Count Constraint

Production Constraint

Production Count Constraint

Demand Constraint

Expression Constraint

Flow Constraint¶

User may add flow constraint based on minimum, maximum or conditional minimum requirements.

Flow Constraint Name: User may give unique constraint name for any constraint, it is an optional field.

ItemType/Source Type/Destination Type: User may choose For All/For Each/For Any based on constraint.

“For All” is selected to apply constraint at aggregated level.

“For Each” is selected to apply constraint for each member.

“For Any” is selected to apply ration constraint over selected member.

Item/Source Location/Destination Location: Specify All/group/individual member for which this constraint applies to.

Flow Requirement/ Flow Basis: Enter constraint quantity/volume/weight as per constraint requirement in Flow Requirement and Flow Basis.

Constraint Type: Enter Min/Max/Fixed/Condition Min/Define as per constraint requirement. Define is used to define custom constraint in expression constraints. For Define type, user must provide unique constraint name and must not have “For Each” type of constraint.

Constraint Status: Enable or Disable a constraint by setting this field to Active/Inactive.

ColumnNames |

Values |

|---|---|

FlowConstraintName |

Test_001 |

ItemType |

ForAll |

Item |

All |

SourceType |

ForEach |

SourceLocation |

DC_001 |

DestinationType |

ForAll |

DestinationLocation |

All |

PeriodType |

ForAll |

PeriodName |

All |

FlowRequirement |

1000 |

FlowBasis |

Weight |

ConstraintType |

Max |

ConstraintStatus |

Active |

ColumnNames |

Values |

|---|---|

FlowConstraintName |

Test_001 |

ItemType |

ForAll |

Item |

All |

SourceType |

ForEach |

SourceLocation |

DC_001 |

DestinationType |

ForAll |

DestinationLocation |

All |

PeriodType |

ForAll |

PeriodName |

All |

FlowRequirement |

200 |

FlowBasis |

Quantity |

ConstraintType |

Max |

ConstraintStatus |

Active |

ColumnNames |

Values |

|---|---|

FlowConstraintName |

Test_001 |

ItemType |

ForAll |

Item |

All |

SourceType |

ForEach |

SourceLocation |

(Group) All DC |

DestinationType |

ForAll |

DestinationLocation |

All |

PeriodType |

ForAll |

PeriodName |

All |

FlowRequirement |

1200 |

FlowBasis |

Quantity |

ConstraintType |

ConditionalMinimum |

ConstraintStatus |

Active |

ColumnNames |

Values |

|---|---|

FlowConstraintName |

Test_001 |

ItemType |

ForAny |

Item |

<Salience in (‘Strong’)> |

SourceType |

ForEach |

SourceLocation |

MH1_BBL |

DestinationType |

ForAll |

DestinationLocation |

All |

PeriodType |

ForEach |

PeriodName |

All |

FlowRequirement |

0.8 |

FlowBasis |

CaseEquivalent |

ConstraintType |

Max |

ConstraintStatus |

Active |

Flow Count Constraint¶

User may add flow count constraint to restrict count w.r.t to facility, customer, period, or items.

Flow Constraint Name: User may give unique constraint name for any constraint, it is an optional field.

ItemType/Source Type/Destination Type/Period Type: User may choose For All/For Each/ For Any based on constraint.

“For All” is selected to apply constraint at aggregated level.

“For Each” is selected to apply constraint for each member.

“For Any” is selected to apply constraint count out of these items/source/destination.

Item/Source Location/Destination Location/Period Type: Specify All/group/individual member for which this constraint applies to.

Flow Count Value: Enter constraint count as per constraint requirement.

Constraint Type: Enter Min/Max/Fixed/Condition Min/Define as per constraint requirement. Define is used to define custom constraint in expression constraints. For Define type, user must provide unique constraint name and must not have “For Each” type of constraint.

Constraint Status: Enable or Disable a constraint by setting this field to Active/Inactive

ColumnNames |

Values |

|---|---|

FlowConstraintName |

Test_001 |

ItemType |

ForAll |

Item |

All |

SourceType |

ForAny |

SourceLocation |

All |

DestinationType |

ForEach |

DestinationLocation |

DC_001 |

PeriodType |

ForAll |

PeriodName |

All |

FlowCountValue |

2 |

ConstraintType |

Max |

ConstraintStatus |

Active |

ColumnNames |

Values |

|---|---|

FlowConstraintName |

Test_001 |

ItemType |

ForEach |

Item |

All |

SourceType |

ForAny |

SourceLocation |

All |

DestinationType |

ForEach |

DestinationLocation |

All |

PeriodType |

ForAll |

PeriodName |

All |

FlowCountValue |

1 |

ConstraintType |

Max |

ConstraintStatus |

Active |

ColumnNames |

Values |

|---|---|

FlowConstraintName |

Test_001 |

ItemType |

ForAll |

Item |

All |

SourceType |

ForAll |

SourceLocation |

All |

DestinationType |

ForAny |

DestinationLocation |

(Group) All DC |

PeriodType |

ForAll |

PeriodName |

All |

FlowCountValue |

1 |

ConstraintType |

Max |

ConstraintStatus |

Active |

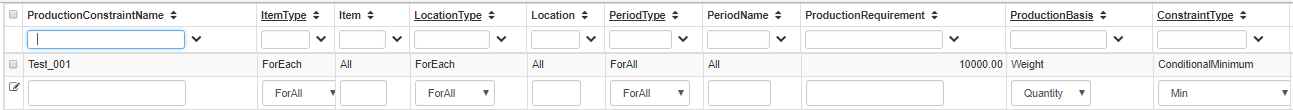

Production Constraint¶

User may add production specific constraint with respect to capacities or requirements.

Production Constraint Name: User may give unique constraint name for any constraint, it is an optional field.

ItemType/Location Type/Period Type: User may choose For All/For Each based on constraint.

“For All” is selected to apply constraint at aggregated level.

“For Each” is selected to apply constraint for each member.

Item/Location/Period: Specify All/group/individual member for which this constraint applies to.

Production Requirement/ Production Basis: Enter constraint quantity/volume/weight as per constraint requirement in Production Requirement and Production Basis

Constraint Type: Enter Min/Max/Fixed/Condition Min/Define as per constraint requirement. Define is used to define custom constraint in expression constraints. For Define type, user must provide unique constraint name and must not have “For Each” type of constraint.

Constraint Status: Enable or Disable a constraint by setting this field to Active/Inactive

ColumnNames |

Values |

|---|---|

ProductionConstraintName |

Test_001 |

ItemType |

ForEach |

Item |

All |

LocationType |

ForEach |

Location |

All |

PeriodType |

ForAll |

PeriodName |

All |

ProductionRequirement |

10000 |

ProductionBasis |

Weight |

ConstraintType |

ConditionalMinimum |

ConstraintStatus |

Active |

Production Count Constraint¶

User may add count constraint to restrict number of location, item or period or any combination.

Production Constraint Name: User may give unique constraint name for any constraint, it is an optional field.

ItemType/Location Type/Period Type: User may choose For All/For Each/For Any based on constraint.

“For All” is selected to apply constraint at aggregated level.

“For Each” is selected to apply constraint for each member.

“For Any” is selected to apply constraint count out of these items/location/period.

Item/Location/Period: Specify All/group/individual member for which this constraint applies to.

Production Count Value: Enter constraint count as per constraint requirement.

Constraint Type: Enter Min/Max/Fixed/Condition Min/Define as per constraint requirement. Define is used to define custom constraint in expression constraints. For Define type, user must provide unique constraint name and must not have “For Each” type of constraint.

Constraint Status: Enable or Disable a constraint by setting this field to Active/Inactive

ColumnNames |

Values |

|---|---|

ProductionConstraintName |

Test_001 |

ItemType |

ForAny |

Item |

All |

LocationType |

ForEach |

Location |

MFG_001 |

PeriodType |

ForEach |

PeriodName |

All |

ProductionCountValue |

3 |

ConstraintType |

Max |

ConstraintStatus |

Active |

Inventory Constraint¶

User may add inventory specific constraint with respect to capacities or requirements.

Inventory Constraint Name: User may give unique constraint name for any constraint, it is an optional field.

ItemType/Location Type/Period Type: User may choose For All/For Each based on constraint.

“For All” is selected to apply constraint at aggregated level.

“For Each” is selected to apply constraint for each member.

Item/Location/Period: Specify All/group/individual member for which this constraint applies to.

Inventory Requirement/ Inventory Basis: Enter constraint quantity/volume/weight as per constraint requirement in Inventory Requirement and Inventory Basis

Inventory Type: Enter inventory type on which constraint is applicable. Inventory Types can be: Ending Inventory/Cycle Stock/Total Inventory/Turn Estimated Inventory. Check “Inventory Output” table to understand what each inventory type means.

Constraint Type: Enter Min/Max/Fixed /Condition Min/Define as per constraint requirement. Define is used to define custom constraint in expression constraints. For Define type, user must provide unique constraint name and must not have “For Each” type of constraint.

Constraint Status: Enable or Disable a constraint by setting this field to Active/Inactive

ColumnNames |

Values |

|---|---|

InventoryConstraintName |

Test_001 |

ItemType |

ForEach |

Item |

All |

LocationType |

ForEach |

Location |

All |

PeriodType |

ForAll |

PeriodName |

All |

InventoryRequirement |

10000 |

InventoryBasis |

Weight |

InventoryType |

EndingInventory |

ConstraintType |

ConditionalMinimum |

ConstraintStatus |

Active |

Inventory Count Constraint¶

User may add count constraint to restrict number of location, item or period or any combination.

Inventory Constraint Name: User may give unique constraint name for any constraint, it is an optional field.

ItemType/Location Type/Period Type: User may choose For All/For Each/For Any based on constraint.

“For All” is selected to apply constraint at aggregated level.

“For Each” is selected to apply constraint for each member.

“For Any” is selected to apply constraint count out of these items/location/period.

Item/Location/Period: Specify All/group/individual member for which this constraint applies to.

Inventory Count Value: Enter constraint count as per constraint requirement.

Constraint Type: Enter Min/Max/Fixed /Condition Min/Define as per constraint requirement. Define is used to define custom constraint in expression constraints. For Define type, user must provide unique constraint name and must not have “For Each” type of constraint.

Constraint Status: Enable or Disable a constraint by setting this field to Active/Inactive

ColumnNames |

Values |

|---|---|

InventoryConstraintName |

Test_001 |

ItemType |

ForAny |

Item |

All |

LocationType |

ForEach |

Location |

DC_001 |

PeriodType |

ForAll |

PeriodName |

All |

InventoryCountValue |

3 |

ConstraintType |

Max |

ConstraintStatus |

Active |

Demand Constraint¶

In case of shortfall model, user may addd demand constraints to specify shortfall for Selected SKU/Market

Demand Constraint Name: User may give unique constraint name for any constraint, it is an optional field.

ItemType/Customer Type/Period Type: User may choose For All/For Each based on constraint.

“For All” is selected to apply constraint at aggregated level.

“For Each” is selected to apply constraint for each member.

Item/Customer/Period: Specify All/group/individual member for which this constraint applies to.

Demand Requirement/ Demand Basis: Enter constraint quantity/volume/weight as per constraint requirement in Demand Requirement and Demand Basis.

Constraint Type: Enter Min/Max/Fixed/Condition Minimum as per constraint requirement.

Constraint Status: Enable or Disable a constraint by setting this field to Active/Inactive

ColumnNames |

Values |

|---|---|

ItemType |

ForEach |

Item |

KFESC5 |

CustomerType |

ForEach |

Customer |

Arunachal Pradesh |

PeriodType |

ForAll |

PeriodName |

All |

DemandRequirement |

60 |

DemandBasis |

Quantity |

ConstraintType |

Fixed |

ConstraintStatus |

Active |

Expression Constraint¶

User may define expression based on “Define” type expressions in other constraint tables.

Constraint Name: User may give unique constraint name for any constraint, it is an optional field.

Coefficient1: Coefficient which is multiplied by expression 1.

Expression1: “Define” type constraint name which is defined in any constraint table.

Coefficient2: Coefficient which is multiplied by expression 2.

Expression2: “Define” type constraint name which is defined in any constraint table.

Constraint Type: Enter Min/Max/Fixed/Condition Minimum as per constraint requirement.

Constraint Value: Enter constraint value as per constraint requirement.

Constraint Status: Enable or Disable a constraint by setting this field to Active/Inactive.

ColumnNames |

Values |

|---|---|

ConstraintName |

Test_001 |

Coefficient1 |

1 |

Expression1 |

production_count_001 |

Coefficient2 |

1 |

Expression2 |

flow_count_001 |

ConstraintValue |

1 |

ConstraintType |

Max |

ConstraintStatus |

Active |

Custom Objective¶

User may define exception in cost applied for a specified SKU/ Brewery/ Market

SourceLocation: Provide Brewery for which exception cost is applicable, if not applicable select All.

DestinationLocation: Provide Market for which exception cost is applicable, if not applicable select All.

Item: Provide SKU for which exception cost is applicable, if not applicable select All.

PeriodName: Provide Period for which exception cost is applicable, if not applicable select All.

Mode: Provide mode for which exception cost is applicable, if not applicable select All.

CostHeader: Provide cost header for which exception cost applicable, For e.g. ExportFee, ImportFee etc.

Value: Provide numeric value as applicable.

CostBasis: Select Cost basis as Quantity/Weight/Volume/CaseEquivalent as applicable.

TableName: Provide table name in which cost header is present. For e.g. if cost header is ImportFee, select TransportationPolicies table, if cost header is COP, select sourcing policies table.

ObjectiveStatus: Enable or Disable a exception cost by setting this field to Active/Inactive.

ColumnNames |

Values |

|---|---|

SourceLocation |

<locstate not in (‘JAMMU & KASHMIR’)> |

DestinationLocation |

Jammu & Kashmir |

Item |

<Size in ( 500 )> |

Period |

All |

Mode |

All |

CostHeader |

ImportFee |

Value |

960 |

CostBasis |

Quantity |

TableName |

TransportationPolicies |

Objective Status |

Active |